Reliable Commercial Refrigeration Equipment Manufacturer

Shandong Zhengkang Electric Appliance Co., Ltd. is located in Boxing County, Shandong Province, the hometown of Han filial son Dong Yong. It is known as the “Chinese Kitchen Capital” and “Jiangbei Wenzhou”.It is an area with superior geographical location, beautiful environment, convenient transportation and communication, and developed industry and commerce, and has the largest wholesale market for black and white iron in Jiangbei.Our company has strong technical strength, a huge production scale, and broad development prospects. We specialize in the research, development, production, and sales of specialized refrigeration equipment such as commercial refrigerators, refrigeration workbenches, mother and child cabinets, and small vegetable refrigerators.

Learn More about ZhengkangHot Selling Commercial Refrigeration Equipments

Types of Our Commercial Refrigeration Equipment

Get Your Custom Commercial Refrigeration Equipment

Zhengkang is a trusted commercial refrigeration equipment manufacturer with years of experience in creating high-quality preservation solutions for various industries. It specializes in producing high-quality refrigeration equipment to meet various customer needs. Here are your custom choices:

The Production Process of Refrigeration Equipment

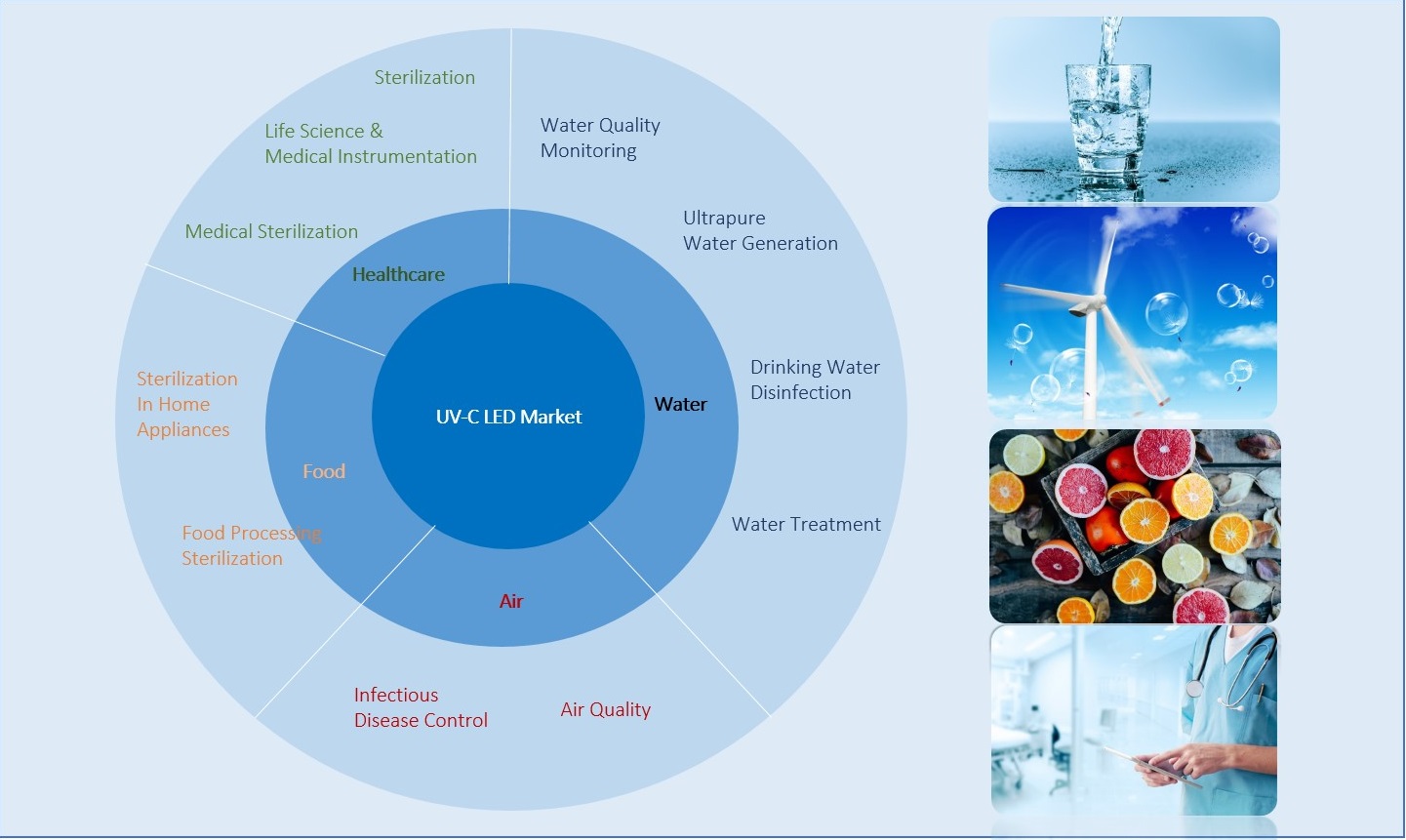

Commercial refrigeration equipment manufacturers provide a wide range of products used in various industries, including food service, retail, and healthcare. These manufacturers design, produce, and distribute equipment such as refrigerators, freezers, display cases, ice machines, and other refrigeration units.

Design Phase

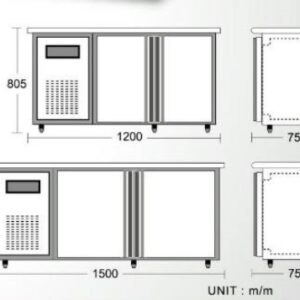

- Needs Analysis: Based on customer requirements, determine the refrigeration capacity, temperature range, and operating environment of the equipment.

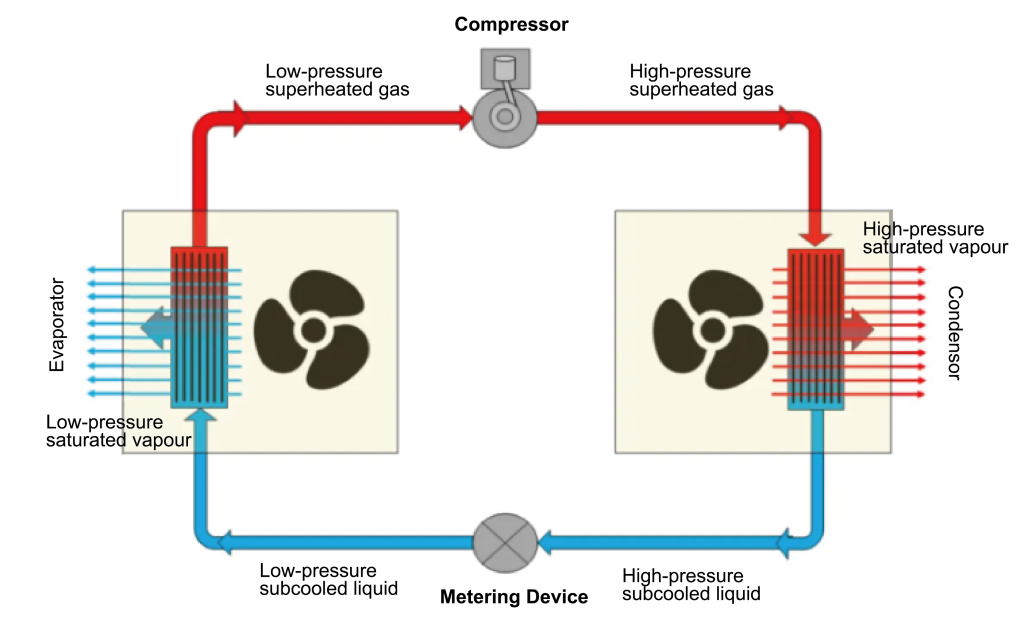

- Scheme Design: According to the needs analysis, select suitable refrigerants, compressors, evaporators, condensers, and other components, and conduct system design.

- Drafting: Based on the design scheme, draw detailed equipment drawings, including general assembly drawings and part drawings.

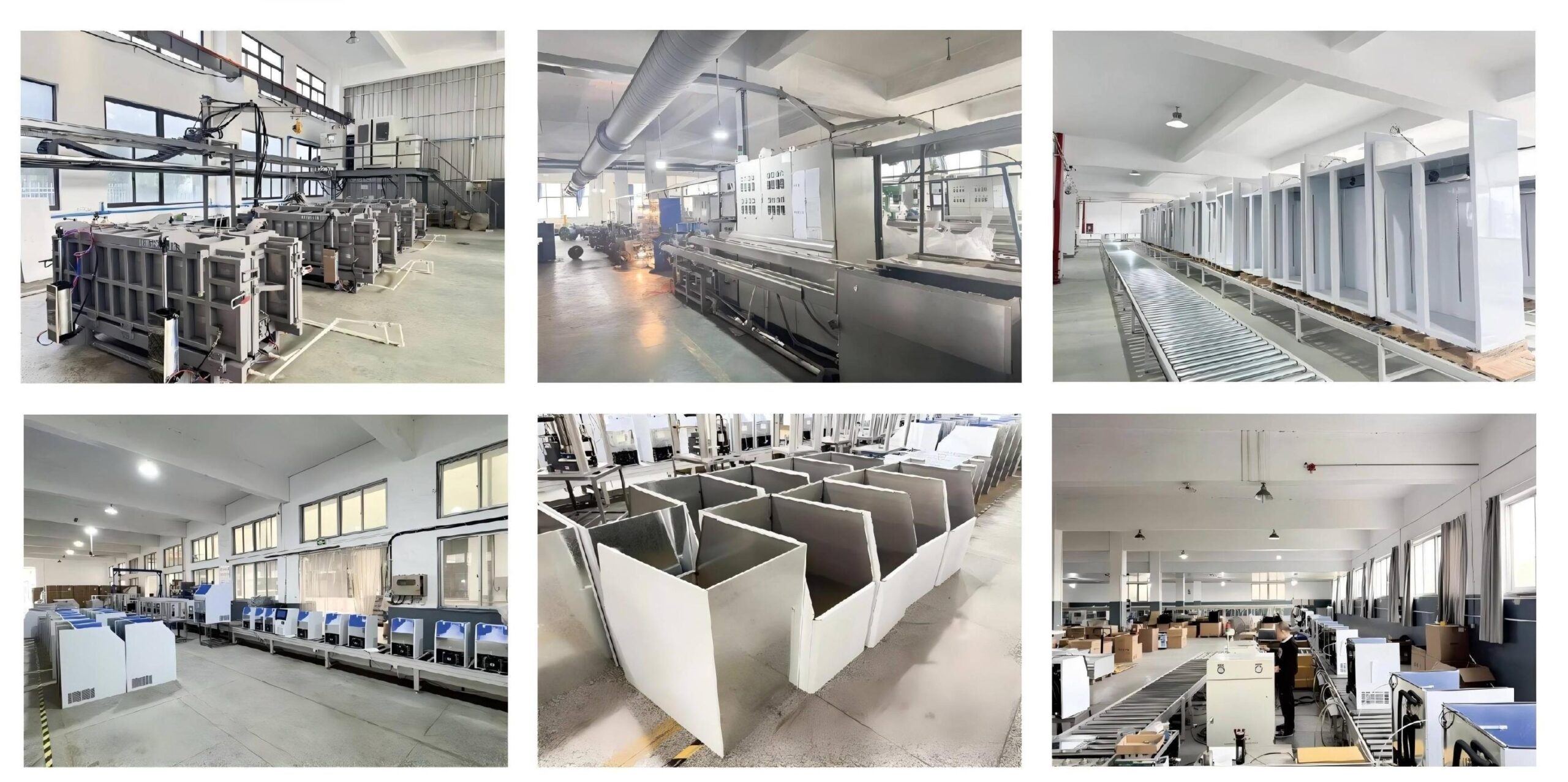

Production Phase

1.Component Processing:

- Sheet Metal Processing: Cut, bend, and weld the equipment’s shell, pipes, and other parts according to the drawings.

- Piping Processing: Manufacture the refrigeration system’s piping, including suction piping, discharge piping, and liquid piping.

- Processing of Other Components: Process core components such as compressors, evaporators, and condensers.

2.Assembly:

- Component Assembly: Assemble the processed components according to the drawings, connect the piping, and install valves.

- Electrical Connection: Connect the wires, install the control panel, and realize the electrical control of the equipment.

- Refrigerant Charging: Charge the refrigerant into the system and perform vacuum treatment.

3.Installation Phase

- Site Survey: Conduct a survey of the installation site and determine the installation location of the equipment.

- Foundation Installation: Install the foundation of the equipment to ensure that the equipment is level.

- Equipment Installation: Hoist the equipment to the designated position and connect it to the piping and electrical system.

- Commissioning: Commission the equipment to ensure its normal operation.

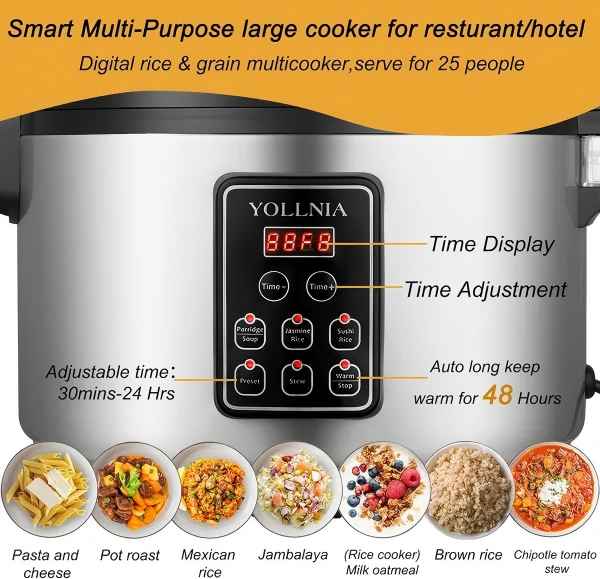

Design Details of Commercial Rice Steamer

Design Considerations:

Safety:

Ensure the steamer is safe to use and complies with relevant safety standards.

Consider features like automatic shut-off, non-slip feet, and heat-resistant handles.

Efficiency:

Design the steamer to cook rice quickly and efficiently while using minimal energy.

Ease of Use:

Make the steamer easy to operate and clean.

Consider user-friendly controls and a removable cooking chamber.

Durability:

Use high-quality materials and construction techniques to ensure the steamer is durable and long-lasting.

Aesthetics:

Design the steamer to have a modern and appealing appearance that complements kitchen decor.

Key Components:

Cooking Chamber:

Made of durable, non-stick material (e.g., stainless steel, Teflon) to prevent sticking and facilitate easy cleaning. Should have a tight-fitting lid to retain moisture and ensure even cooking.The bottom should be perforated to allow steam to circulate freely.

Heating Element:

Located below the cooking chamber.Can be electric, gas, or induction for various cooking methods.Should provide sufficient heat to generate steam efficiently.

Water Reservoir:

Placed below the heating element. Should have a clear water level indicator to prevent running out of water. A safety feature to automatically shut off the heating element when the water level is low is recommended.

Controls:

Simple and intuitive controls for easy operation.

May include a timer, temperature settings, and a keep-warm function.

Benefits of Commercial Refrigeration Equipment Manufacturer

Industry-Specific Solutions: They offer specialized equipment for various industries, such as restaurants, grocery stores, hospitals, and laboratories.

Advanced Technology: Manufacturers incorporate the latest technology to ensure optimal performance, energy efficiency, and longevity.

Health Code Adherence: Manufacturers design products that comply with health and safety regulations.

Advanced Features: Many manufacturers offer features like automatic defrosting, insulation improvements, and efficient compressors to minimize energy consumption.

Installation and Maintenance: Manufacturers often provide professional installation and maintenance services to ensure optimal equipment performance.

Technical Assistance: They offer technical support and troubleshooting assistance to address any issues that may arise.

Product Development:Commercial refrigeration equipment manufacturer continually research and develop new technologies to improve refrigeration efficiency, reliability, and features.

Industry Trends: They stay updated on industry trends and regulations to offer cutting-edge solutions.

Why Choose Us as a Commercial Refrigeration Equipment Manufacturer

Professional and Advanced Equipment

With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice. Advanced equipment creates high-quality products for you.

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Improve product sales and technical after-sales service. 24 hours online video call, actively solve problems for customers

What Our Other Customers Say About Us

After-Sales Support

1. Help Desk and Technical Support Services

After sales and technical support services are various services provided to customers after the product is sold, aimed at ensuring that the product can continue to operate stably and maximize its value.

2. Real-Time Online Support

Real-time online support includes email, chat, forums, and a social media interface (and monitoring) that assists in responding to public complaints and criticisms. This may include handling returns or repairs.

3. Automated Customer Service Lines

Automated customer service lines can give advice and solutions to frequent or even more complex issues and questions. Typically, rather than employing more human customer service representatives, automated responses and bots allow customers to easily access support at any time, either by phone or online.

4. Automated Support Resources

This may include easily-accessible online solutions that involve forums where customers may interact with other users or experts, post questions, or search for answers.

Our Partner

FAQ of Commercial Refrigeration Equipment Manufacturer

Commercial refrigeration equipment manufacturer offer a wide range of products, including refrigerators, freezers, display cases, ice machines, and other refrigeration units.

Commercial refrigeration equipment manufacturer use advanced technologies and quality control measures to ensure their products meet high standards of reliability and performance.

.

Energy Consumption Rating:

- Energy Star Rating: Look for units with the Energy Star label, which indicates that the equipment meets or exceeds federal energy efficiency standards.

- Efficiency Ratings: Some countries or regions have specific energy efficiency ratings for commercial refrigeration equipment, such as the European Union’s Energy Efficiency Index (EEI).

- Kilowatt-Hour (kWh) Consumption: The unit’s annual energy consumption is often expressed in kilowatt-hours (kWh). A lower kWh rating indicates greater energy efficiency.

Factors Affecting Noise Levels:

- Compressor: The compressor is often the primary source of noise in refrigeration units. Newer models with inverter technology or vibration-dampening features can reduce noise levels.

- Fan Motors: Fan motors used for airflow can also contribute to noise. Units with quieter fan motors or sound-absorbing materials can help reduce noise.

- Door Mechanisms: The design and operation of doors can impact noise levels, especially if they are frequently opened and closed.

- Installation Location: The unit’s location within a building can affect noise levels. Placing it in a separate room or using sound-proofing materials can help to isolate noise.

Hinged Doors:

- Swing-Out Doors: These are the most traditional type of door, swinging outward when opened. They are suitable for units with ample space around them.

- Swing-In Doors: These doors swing inward when opened, requiring more space inside the unit. They are often used in walk-in coolers and freezers.

Sliding Doors:

- Sliding Doors: These doors slide horizontally along tracks, saving space and allowing for easier access in tight spaces. They are commonly used in reach-in refrigerators and freezers.

Absolutely! Many commercial refrigeration equipment manufacturers offer installation services. The cost can vary depending on several factors, including:

- Unit Size and Complexity: Larger and more complex units will generally require more time and labor for installation.

- Location: Installation in remote areas or locations with difficult access might incur additional costs.

- Additional Services: If you require additional services, such as electrical wiring or plumbing, these will be added to the total cost.

It’s important to inquire about the manufacturer’s installation services early in the purchasing process. They can provide you with a detailed quote based on your specific needs and location.